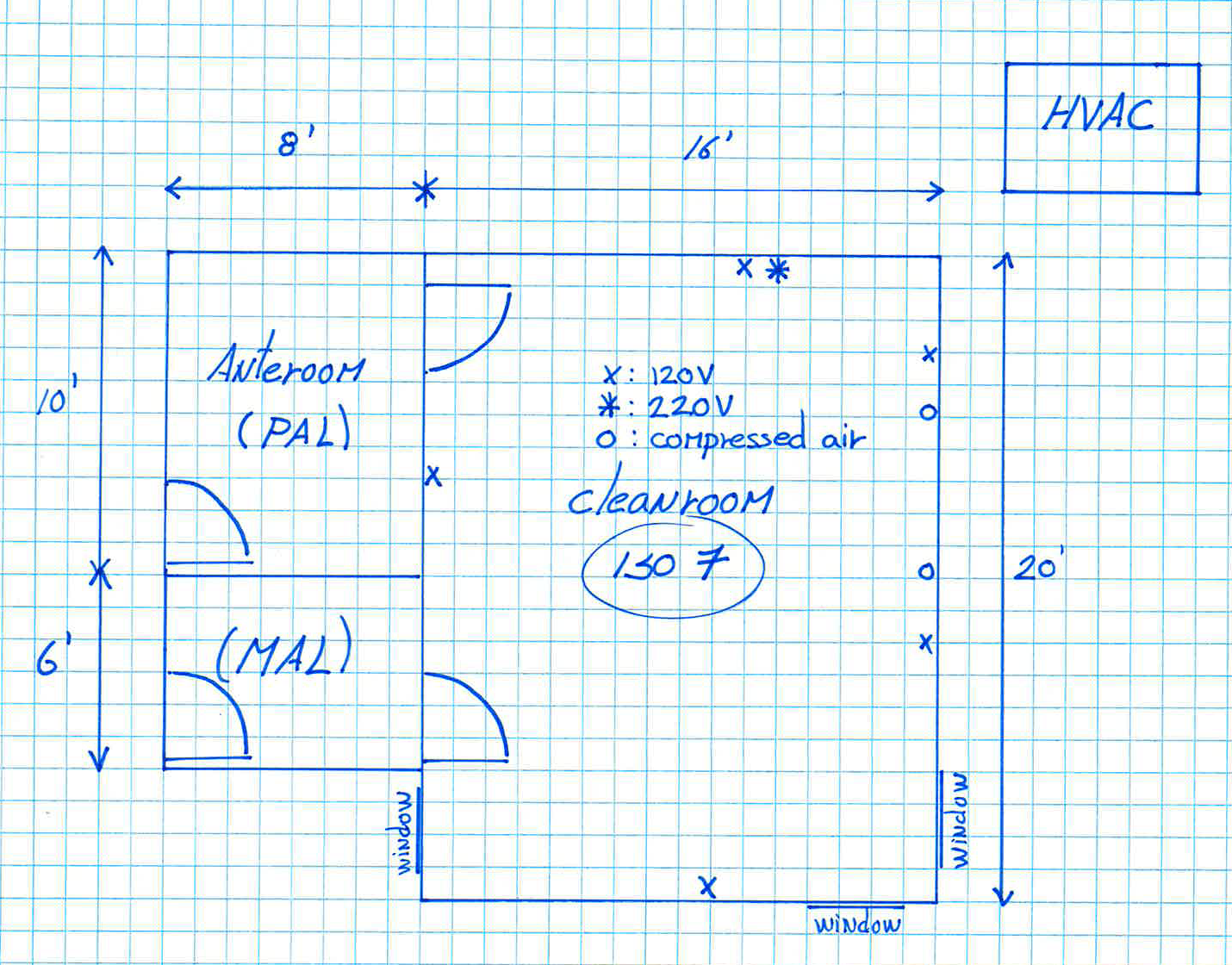

In theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

Iso 8 clean room pressure.

We are one stop source for the successful implementation of any cleanroom development project from concept to completion.

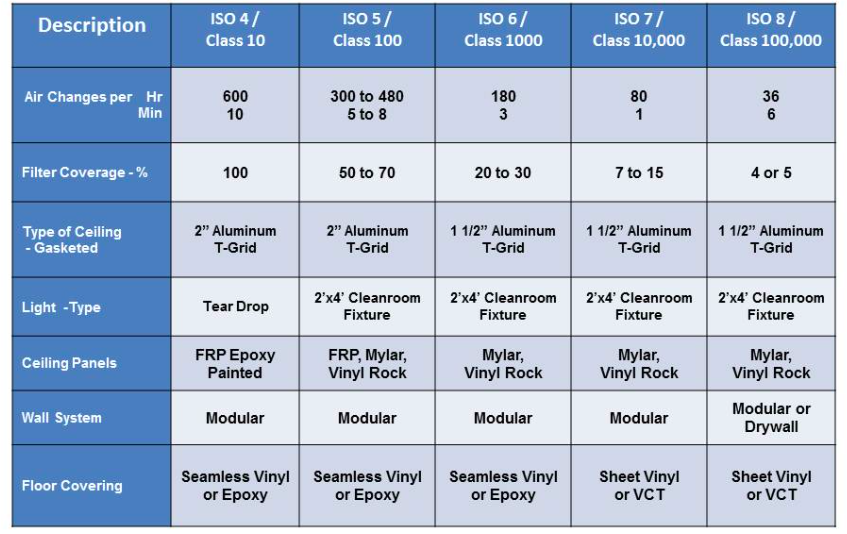

Iso clean room classifications are rated according to how much of a particulate of a specific size exists per cubic meter within a given enclosure see second chart.

I would like to know what is the minimum pressure differential required for iso class 8 clean room.

Cleanroom design and construction.

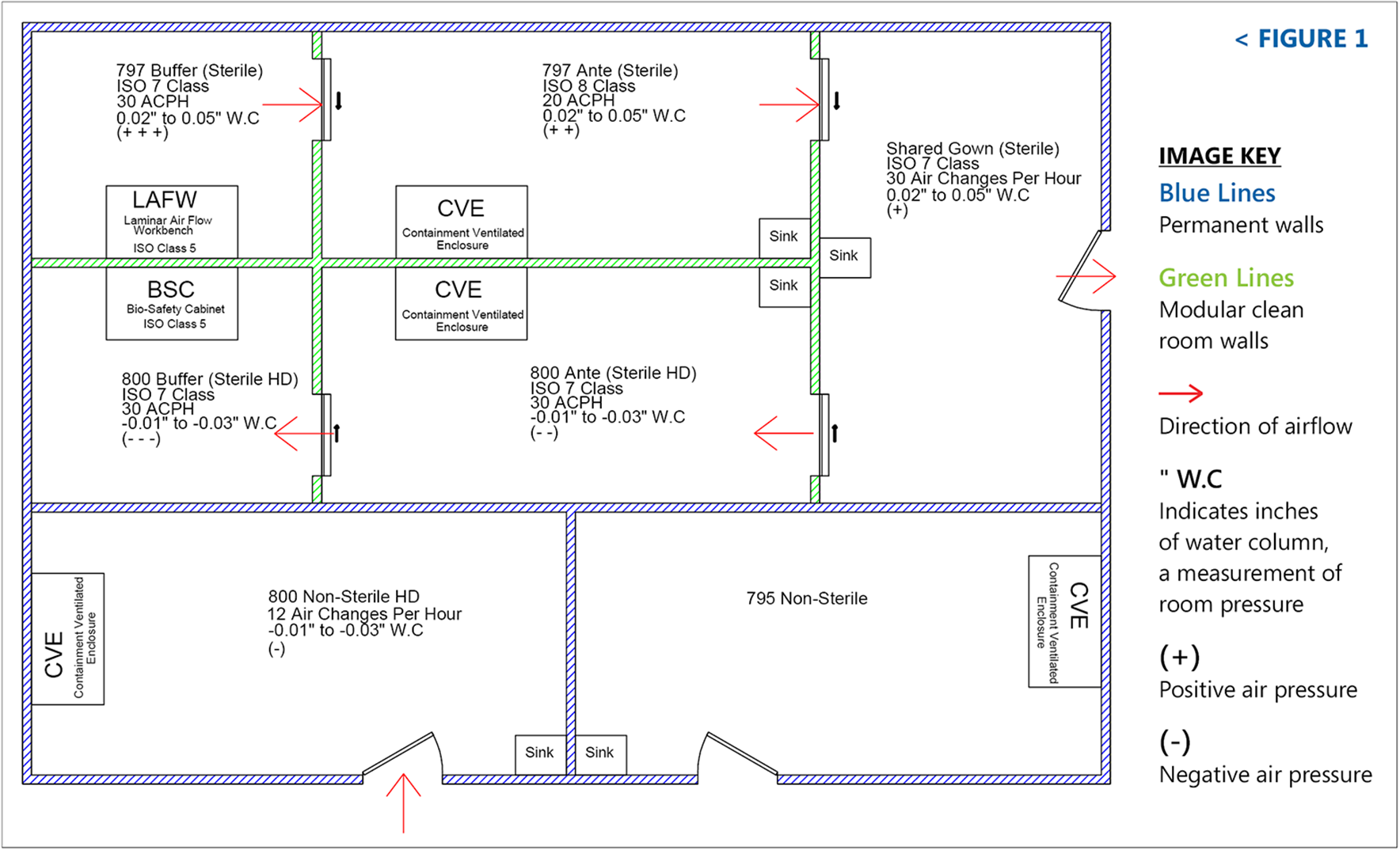

The pressure must be greater in more stringent classified rooms so the air leaks towards the lesser clean rooms.

Temperature humidity and pressure are controlled as.

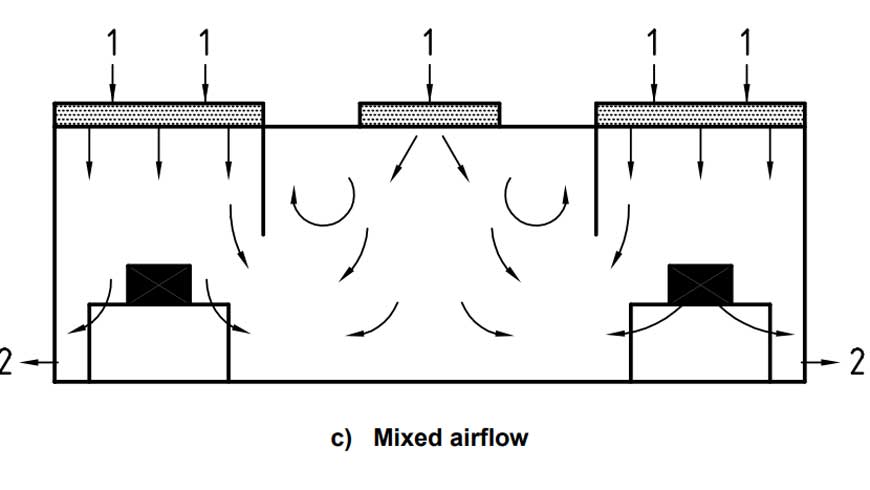

The airflow must be greater in the adjacent room.

Iso 8 clean room clean rooms west inc.

A cleanroom or clean room is a facility ordinarily utilized as a part of specialized industrial production or scientific research including the manufacture of pharmaceutical items integrated circuits crt lcd oled and microled displays.

Clean room classifications are based on an eight class rating system with an iso class 1 cleanroom being rated the most particle free and iso class 8 allowing the most particles.

I am asking this question because one of our clean room has a pressure differential of 0 02 inches water clean room to gowning and 0 01 inches water gowning to outside.

Usually manufacturers will define an airborne particulate concentration standard class such as iso 14644 1 iso 8 at rest outline gowning and a pressure cascade regime defining a clean corridor design or a dirty corridor design.

Is an innovative leader in design engineering manufacturing and construction of clean rooms throughout the us.

Terms definitions and units.

In a negative pressurised cleanroom the opposite occurs.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

Cleanrooms are designed to maintain extremely low levels of particulates such as dust airborne organisms or vaporized particles.

Positive pressure prevents dirty air from entering into the cleanroom.

A cleanroom is defined by iso14644 1 as a room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters e g.

Iso 8 cleanroom particle specifications.

The concentration of particles that are 0 5 µm should be below 3 520 000.