Cleanroom standard cleanroom classification guidelines.

Iso 8 clean room air changes per hour.

Clean room and clean air device classification in relation to gmp 2008.

The above suggested air changes per hour are only a design rule of thumb.

The standard iso 14644 1 2015 does not specify the air changes per hour ach for each cleanroom class because it depends on many factors.

As defined by iso 146144 4 standards.

This table details the recommended air changes per hour for iso 14644 1 2015 cleanrooms and their associated gmp grade and federal standard.

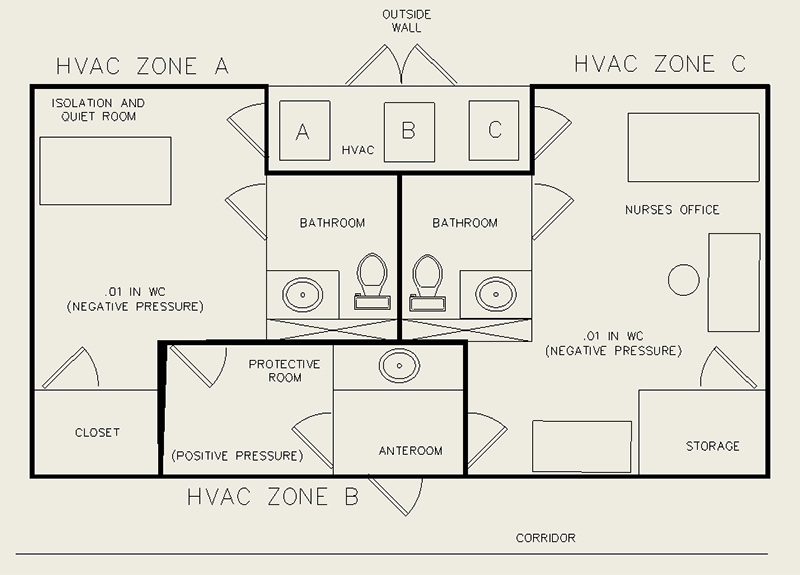

Iso 8 zone 15 25 air changes per hour ante room iso 5 cleanroom class 100 in theory for a classified room not just below a lafw hood to reach iso 5 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 followed by an iso 6 to finally get into the iso 5.

Rooms having 60 air changes per hour will have 60 times air supply then the volume of the room.

A class 5 room can have an air change rate of 400 to 600 times per hour while a class 7 room can change at 50 to 60 changes per hour.

Iso 5 class 100 0 203 0 406 40 80 240 480.

Air changes per hour ceiling coverage.

The ach is the number of total replacements of a room s air in one hour and the iso 14644 1 2015 only tells you the result that you must aim for.

Fda recommends maintaining the minimum 20 air changes per hour for clean rooms.

They should be computed by an hvac cleanroom expert as many aspects must be taken into consideration such as the size of.

Iso 6 class 1 000 0 127 0 203 25 40 150 240.

Iso 8 class 100 000 0 005 0 041 1 8 5 48.

Iso 4 class 10 0 254.

Iso 7 class 10 000 0 051 0 076 10 15 60 90.

Rate of air exchange is expressed as the number of air changes per unit of time and calculated by dividing the volume of air delivered in the unit of time by the volume of the cleanroom or clean zone.

The maximum concentration limits for particles.